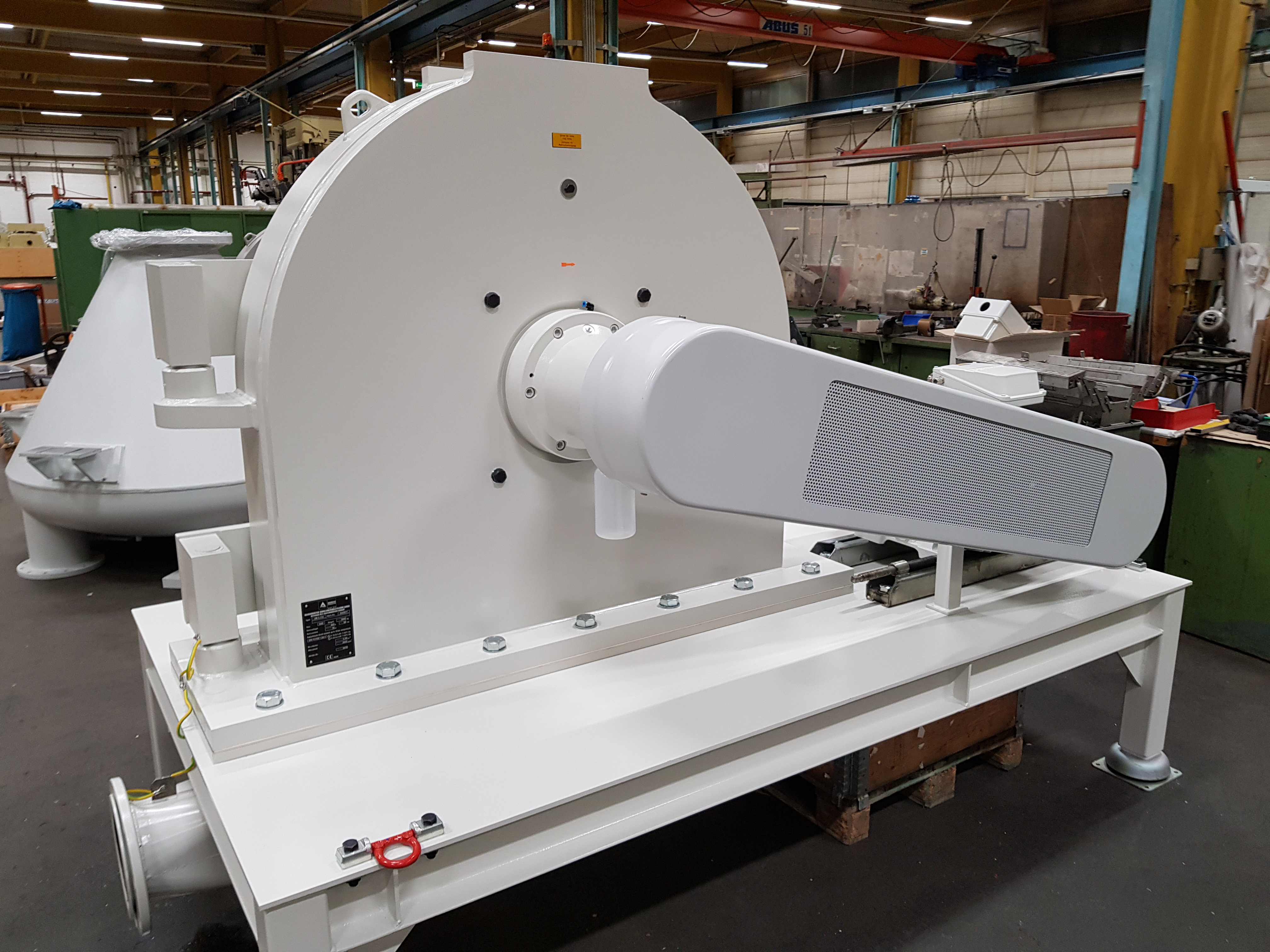

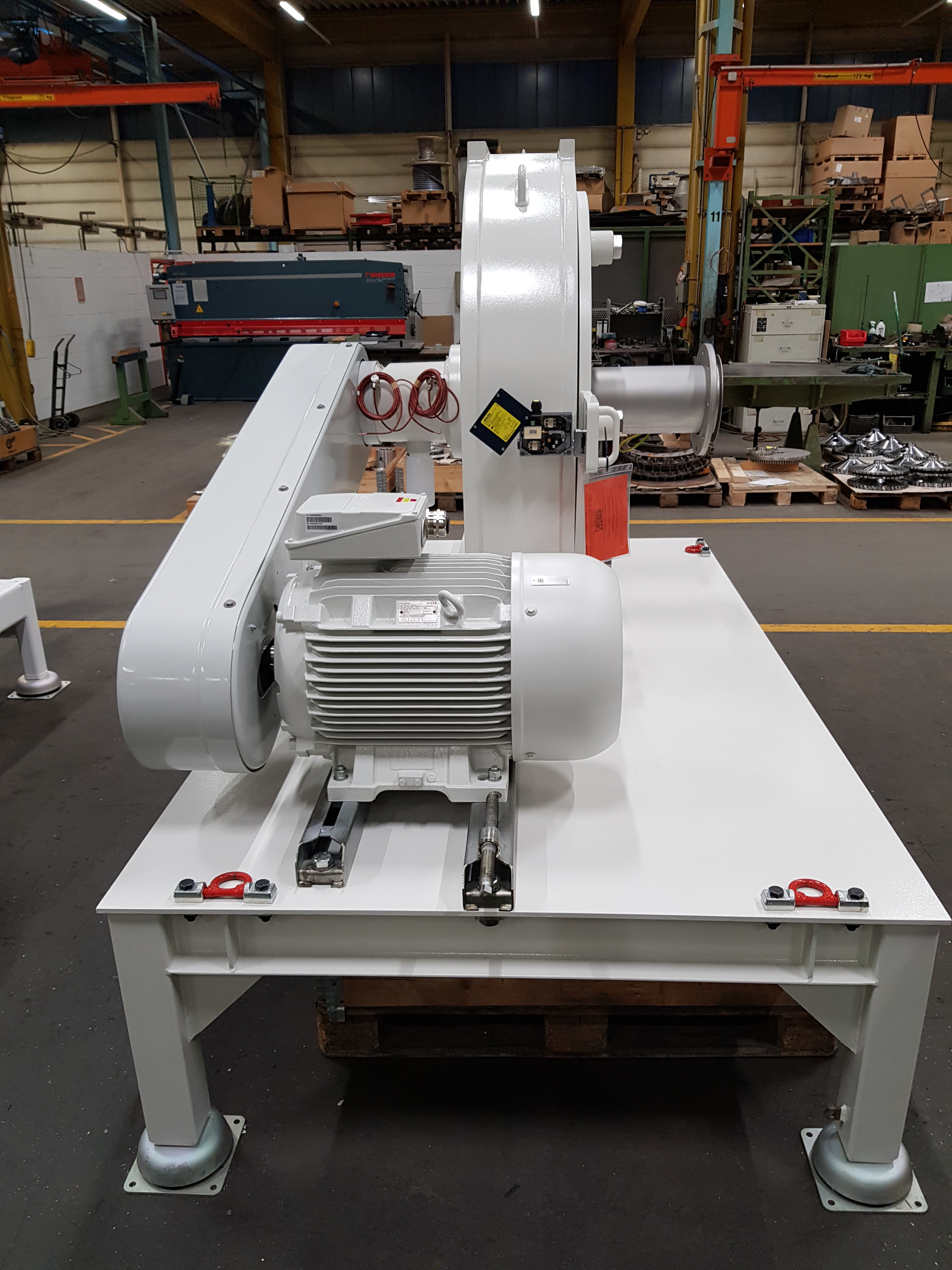

Grinders

Grinding is a common process in the powder handling industry and is generally used to make a specific size of particle. However, grinding is sometimes used to increase the material surface area for the efficacy of chemical reactions. The consistency of the grind and the durability of the material are critical aspects of the grinding process. The UM Series grinders are made from mild or stainless steel, conform to 94/9/EU regulations, and have features that include:

- Compact design for minimal floor space

- Continuous bearing lubrication (optional)

- Dust tight and uses state-of-the-art technology

- Explosion shock resistant design to 10-bar

- Low operating and maintenance costs

UM Series grinders are an economical alternative to conventional grinding systems as they do not need auxiliary equipment such as explosion valves, ventilators and external filter systems.

Need Assistance?

Feel free to contact us for assistance with your pneumatic conveying and powder handling system project. Or use the online form on this page to send us a message. You may also get in touch with us to explore how we can support your organisation with our range of services.

For more information, follow us on our YouTube channel updates on our services for pneumatic conveying and powder handling system projects.