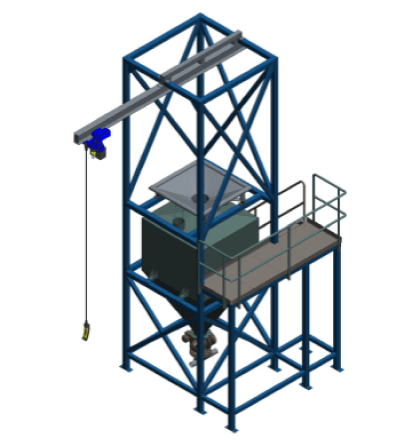

Auto Debagging Systems

We design and fit custom auto debagging solutions that cover a broad range of bags, are simple to operate, and are highly reliable. Our auto debagging systems are cost-effective additions to processing plants, as they:

- Greatly reduce plant labor and overheads

- Improve production rates

- Minimize downtime

Our heavy duty debagger efficiently separates the bag from the material with minimal product carry-over. The system can debag from 100 to 600 bags per hour. The debagging rate depends on the product and the bag construction.

Our auto debagging systems generally work by feeding bags into an in-feed chute. The bags then slide along the chute into a series of rotating blades. These blades slit the bags prior to them entering a rotating trommel screen, which is a perforated tube that tumbles the slit bag to separate the product from the bag. The product drops through the perforations into a feed hopper while the waste bag moves along the tube towards a compactor for disposal.

Need Assistance?

Feel free to contact us for assistance with your pneumatic conveying and powder handling system project. Or use the online form on this page to send us a message. You may also get in touch with us to explore how we can support your organisation with our range of services.

For more information, follow us on our YouTube channel updates on our services for pneumatic conveying and powder handling system projects.