Storage Silos

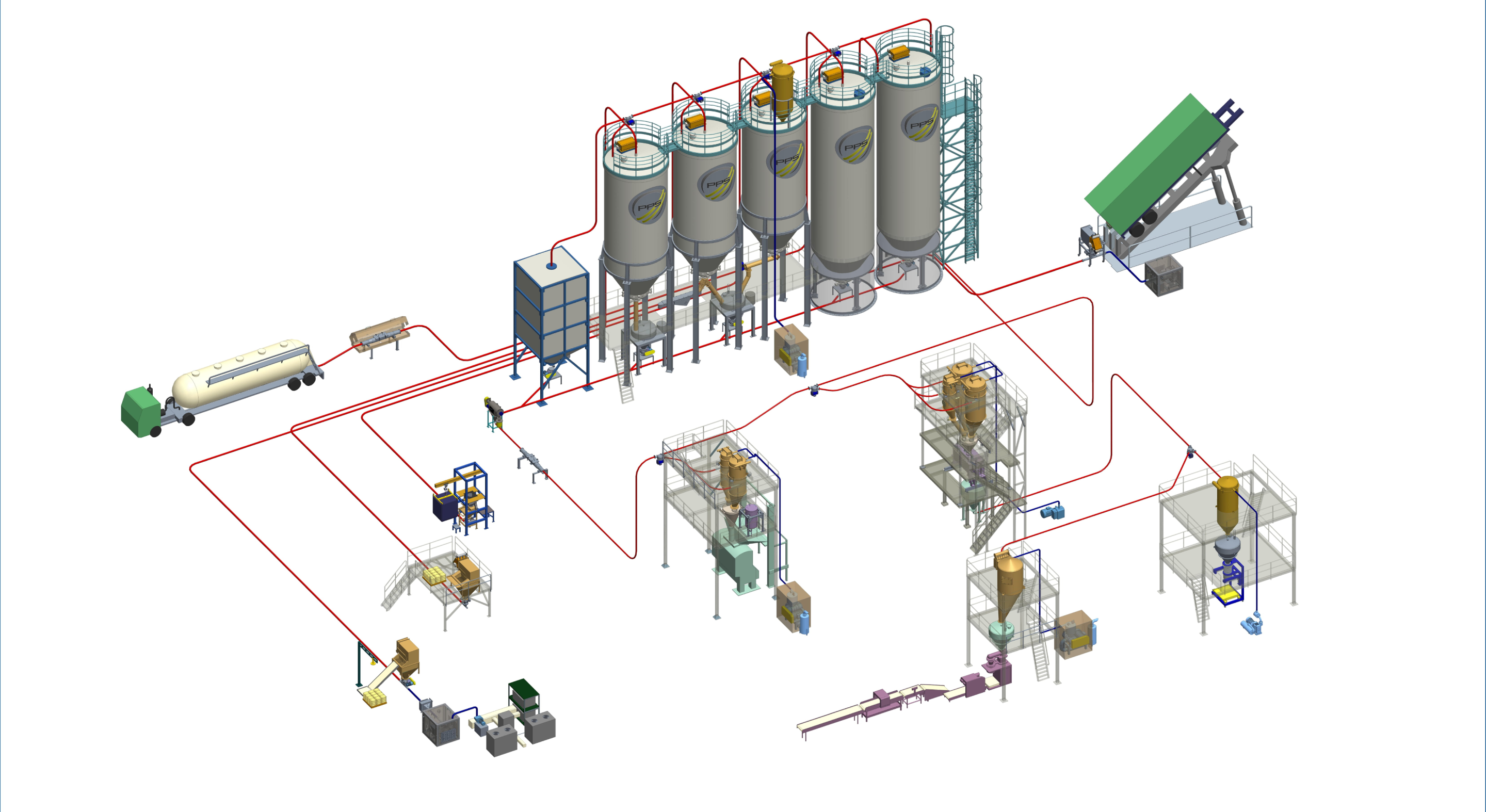

A reliable silo storage system is central to efficient powder handling. Designed for the secure containment of dry bulk materials, these structures protect materials from environmental factors, ensuring product integrity and streamlining production.

Pneu Powders Systems engineers a range of robust storage silos for both indoor and outdoor applications, built with high-quality materials to ensure structural integrity.

Built with high-quality materials, our solutions provide safe, dependable storage. We optimise material flow from delivery to discharge, minimising waste, safeguarding against contamination, and ensuring uninterrupted operational continuity, forming the cornerstone of your bulk handling process.

Silo Storage Systems We Offer

Pneu Powders Systems We engineers bespoke storage silo systems, fully customised to accommodate the operational requirements of your specific material and plant infrastructure.

Metal (Steel & Aluminium) Silo System

Metal silos offer a durable and versatile solution for a vast range of bulk materials. Pneu Powders Systems can engineer your powder storage silo with either leg or skirted supports, depending on structural and operational needs. The choice of metal is critical and is matched to your product characteristics.

- Mild Steel: Valued for its significant strength and cost-effective manufacturing, mild steel is a primary choice for industrial silos. This robust material ensures a long operational life with minimal maintenance, providing a reliable and durable storage solution for diverse non-corrosive material applications.

- Stainless Steel: Stainless steel provides superior sterile and non-reactive properties, making it essential for applications where hygiene is critical. It ensures product integrity when storing liquids and sensitive materials, making it the premier choice for the beverage, pharmaceutical, and agricultural industries.

- Aluminium: Recognised for its excellent strength-to-weight ratio, aluminium silos offer a lightweight yet durable storage solution. Their adaptability and lower price point make them a popular, cost-effective choice, providing flexibility in construction and budget for various suitable material applications.

Fabric Silo System

For indoor applications that require flexibility, fabric silos offer a modern and efficient storage solution. These systems consist of a durable fabric body suspended within a galvanised steel frame, which allows for simple transportation and assembly.

Our fabric silo systems are constructed using TREVIRA®, a high-performance polyester fabric engineered for superior containment and adaptability. This premium material offers several key benefits:

- Exceptionally Durable: Built with robust construction, our systems are engineered to deliver a long and reliable service life, ensuring consistent performance and maximising your long-term investment.

- Prevents Condensation: The fabric is uniquely permeable, allowing air to escape while retaining powder, which protects against moisture build-up and preserves product quality.

- Maintains Product Purity: Its dust-proof and non-toxic properties ensure your stored material remains uncontaminated.

- Customisable Safety Features: Can be specified with anti-static, anti-microbial, or flame-retardant properties to meet stringent safety and hygiene standards.

Silo Systems Designed for Your Products and Applications

What Materials Are These Silo Systems Suitable For?

A safe, reliable and accessible indoor or outdoor storage silo system is crucial to any powder handling plant. These storage structures are designed to contain a variety of dry bulk materials, including:

- Cereals

- Chemicals

- Dairy powders

- Flour

- Mineral

- Mixtures

- Plastics

- Salt

- Starch

- Sugar

Why Choose Pneu Powders’ Silo Storage System

Validated by ISO9001

Our ISO 9001 certification confirms our commitment to rigorous quality management, ensuring a consistently high standard of excellence across all our projects.

Compliance with IECEx standards

Our powder handling equipment is certified to meet IECEx standards, ensuring its suitability for safe and reliable operation in potentially explosive atmospheres.

Meet EU safety regulations under ATEX 2014/34/EC

Our products are engineered to be fully compliant with the ATEX 2014/34/EU directive, meeting all essential health and safety requirements for equipment used in potentially explosive environments.

30+ years of experience with 160 projects completed

For over 30 years, we have delivered expert solutions across more than 160 projects, establishing our firm as a trusted partner for both small and medium-sized enterprises and global industry leaders.

Industries We Serve

Pharmaceutical

Dairy

Petrochemical

Food Processing

Frequently Asked Questions About Silo Storage Systems

Which industries are Pneu Powders Systems’ silo storage solutions suitable for?

Pneu Powders Systems’ silo storage solutions are engineered for a wide range of industries that require the hygienic and precise handling of dry bulk materials. Key sectors include food and beverage processing, dairy, pharmaceuticals, petrochemicals, and oleochemicals, where safe and reliable containment of powders, granules, and pellets is crucial.

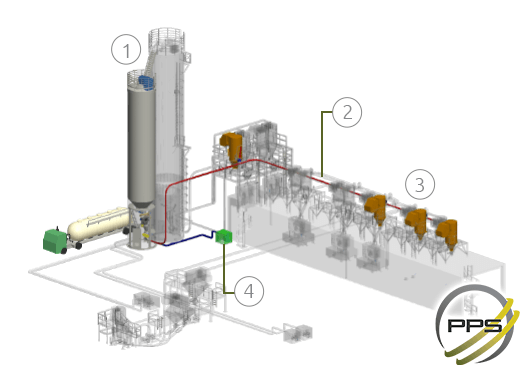

Can the storage silos be integrated with my existing manufacturing processes?

Yes, absolutely. Pneu Powders Systems designs each silo storage system with a total system perspective. Our engineering process focuses on seamless integration, ensuring the silo connects flawlessly with your existing upstream and downstream equipment, such as feeders, pneumatic conveyors, and mixers, to enhance your overall manufacturing process.

Where do you supply your silo storage systems?

Pneu Powders Systems designs and delivers custom-engineered silo storage systems across the Asia-Pacific region. Our primary service area focuses on supporting industrial clients throughout ASEAN countries, including major projects in Malaysia, Indonesia, Thailand, Vietnam, and more.

How can I engage Pneu Powders Systems’ services?

To engage our services, simply reach out to our team of experienced engineers for an initial consultation. We will discuss your project’s specific requirements, operational goals, and material characteristics to begin the process of designing a tailored powder handling solution for your facility, often starting with an on-site assessment.

View Similar Equipment

Need Assistance?

Feel free to contact us for assistance with your pneumatic conveying and powder handling system project. Or use the online form on this page to send us a message. You may also get in touch with us to explore how we can support your organisation with our range of services.

For more information, follow us on our YouTube channel updates on our services for pneumatic conveying and powder handling system projects.