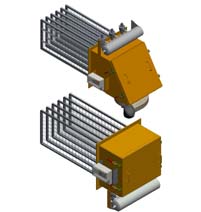

Weighing and Batching Systems

In powder handling and pneumatic conveying systems it is essential to be able to weigh, meter and batch materials, large or small, to create a consistent final product. Applications such as soup mixing, baking recipes, pharmaceutical supplements and confectionery all require a weighing and batching system to ensure their product is of the same quality every production. Pneu Powders Systems offers a wide range of equipment that can suit systems from as small as micro ingredient systems with minuscule doses to 20‑tonne flour silos that meter out materials by the tonne.

Our systems include the following basic features:

- Micro, minor and major dosing systems for materials

- Sanitary, dust-free and safe

- Fast fill or slow trickle filling with optional self-tuning

- Automated top-up systems

- High accuracy load cells and weight control functions

- Continuous weighing systems

Our weighing and batching systems use innovative control panels and recipe management. They include SCADA (Supervisory Control and Data Acquisition) or HMI (Human Machine Interface) and are used for inventory control, reporting and process visualization. These interfaces can be integrated with a management information system for monitoring and process optimization.

Need Assistance?

Feel free to contact us for assistance with your pneumatic conveying and powder handling system project. Or use the online form on this page to send us a message. You may also get in touch with us to explore how we can support your organisation with our range of services.

For more information, follow us on our YouTube channel updates on our services for pneumatic conveying and powder handling system projects.