What is it?

Advantages of Pneumatic Conveyor Systems

Reduced Product Degradation

Non-contaminating

Low Energy Consumption

Compact System Design

Fewer Moving Parts

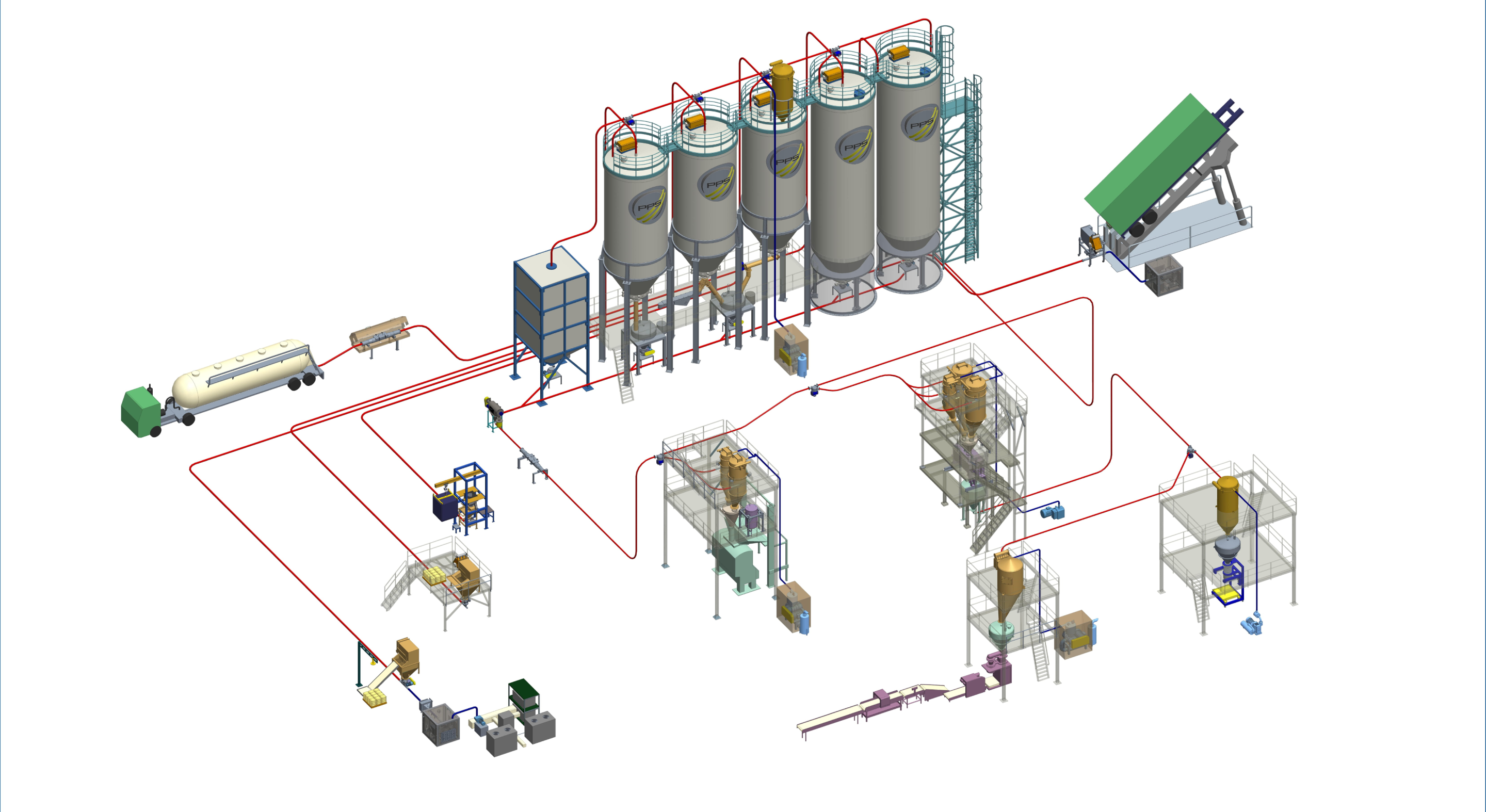

Our Customised Pneumatic Conveying Solutions

Consultation and Site Assessment

The facility’s layout is evaluated to pinpoint operational constraints like space limitations and access points. Moreover, we assess material characteristics such as particle size, bulk density, and abrasiveness to determine system specifications, including throughput rates and transfer distances. These steps ensure the powder conveying system is optimally designed for the operational environment.

Custom Design and Fabrication

Our professional pneumatic conveying system engineers expertly customise designs to meet unique operational requirements. This customisation includes:

- Conveying velocity: Calculating the ideal airspeed to minimise pipe wear and ensure efficient material transport.

- Pipe diameter: Selecting the correct pipe size to balance efficiency and reduce pressure drops.

- Air-to-material ratio: Optimising the air-to-material ratio to prevent blockages and ensure smooth conveying.

- System layout: Designing an optimised path with minimal bends to reduce wear and save energy.

- System pressure: Engineering the system to operate within optimal pressure ranges for specific materials without overloading components.

Maintenance and Support

Beyond design and installation, we provide expert servicing and maintenance for your pneumatic conveying system, ensuring optimal performance. This includes regular diagnostics, proactive replacement of parts prone to wear and tear, and immediate troubleshooting to maintain system efficiency and prevent downtime.

Types of Pneumatic Conveying Systems

There are two key types of pneumatic conveying systems: lean and dense phase. Each has distinct benefits, which are essential for selecting the right application.

Lean Phase/ Dilute Phase

Transport lightweight, non-abrasive materials like flour and sugar over long distances using high velocity and low air pressure. Using high velocity and low air pressure.

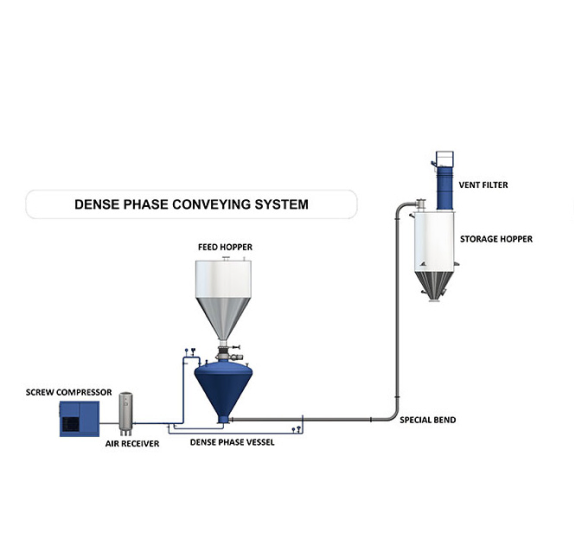

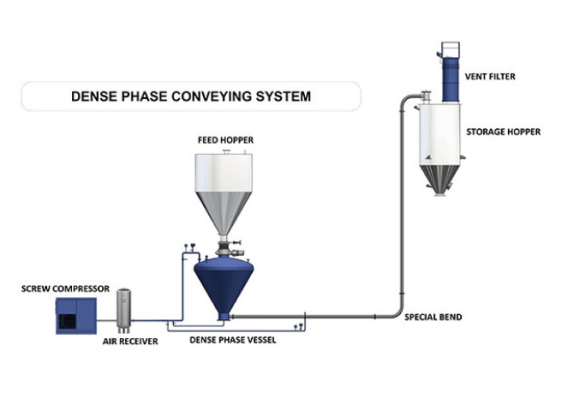

Dense Phase

Transport heavy, bulky, or abrasive materials such as plastics and minerals. Handle heavy, bulky, or abrasive materials such as plastics and minerals.

At Pneu Powders, we specialise in delivering powder handling solutions and pneumatic conveying systems for bulk dry and semi-solid powders. We also provide expert advice on selecting the appropriate pneumatic conveying equipment for your industry and organisation.