Biscuit lines in a manufacturing plants are large and complex, using many materials including flour, fine sugar, palm oil, palm olein and rapeseed oil. The fine sugar is produced onsite by grinding raw granular sugar. The flour comes to the plant in bulk tanker and is loaded to the bulk storage silos located outdoors.

Sugar is pneumatically transferred to receiving or weighing hoppers. These mixers use loss-in or gain-in weight methods to discharge to the mixer. The sugar comes to the plant in either small bags (25 to 50kg) or jumbo bags (500 to 1500kg). They are fed into the twin bag dump station, where an operator manages the tipping. The raw crystalline sugar is fed to grinders and ground into fine or icing sugar. The ground sugar is pneumatically conveyed to the weighing stations on each mixer and discharged accordingly.

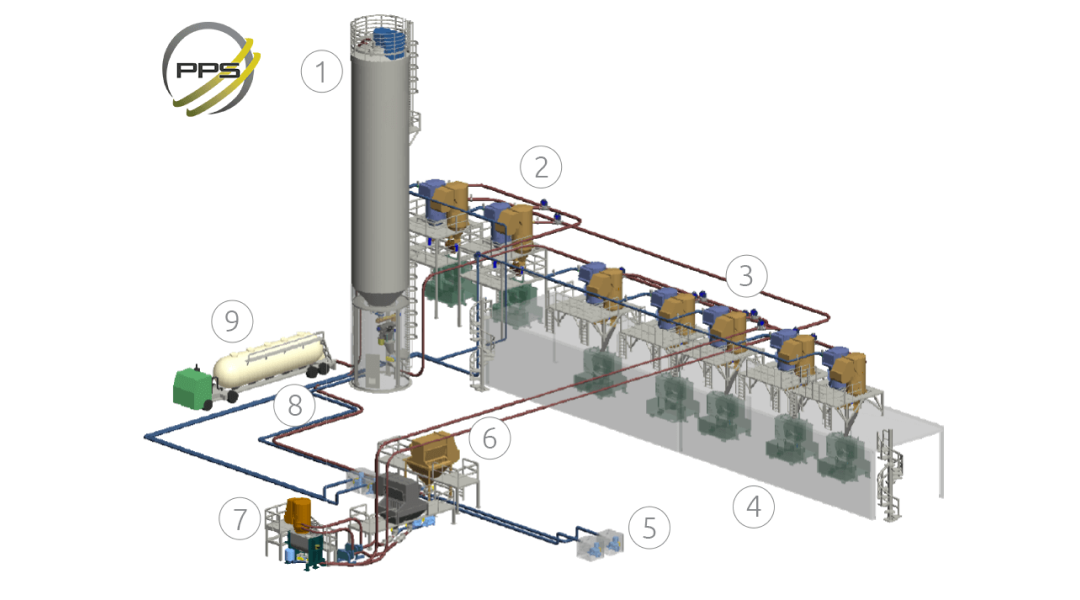

The systems and components used in the biscuit lines of this manufacturing plant example are as follows:

- Exhauster units

- Flour and sugar mixing systems

- Silo and storage system

- Sugar agitation hopper

- Sugar grinder

- Twin small bag dump station

Dispensing and dosing of different kinds of oil-based products are complementary to our expertise in powder handling systems. We have the capability to design systems to transfer water and oil-based products that need to be metered and dosed accurately to specific requirements. These transfer systems use either centrifugal or positive displacement pumps.

Stringent safety protection requirements need to be met when handling flour and especially fine sugar. Compliance with various equipment, health and safety standards is mandatory due to the explosive nature of these materials. Our capability to design powder handling systems and pneumatic conveying that are fully compliant with the ATEX (European) and NFPA (USA) safety standards is vital in such projects. We work with many certification companies that verify our installed systems are fully compliant to ATEX and NFPA standards.