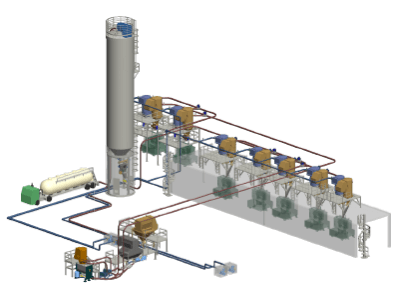

At first, the design and implementation of this project seemed relatively straightforward. The initial scope was to integrate a new flour handling system into an existing silo storage system; however, budget constraints had the food processing plant subsequently request the new system to also integrate into the existing minor ingredient system. The addition of this requirement was, however, to make the project very complicated. It was discovered that the existing minor ingredient handling system was under-designed. The unit would not able to cope with the increased throughput and thus needed to be upgraded. The necessary improvements were able to be engineered and successfully implemented despite the unit being supplied by an international third party. The project tasks were carried out in two parts.

Firstly, the new flour silo and flour handling system for the second bread line was integrated with the existing flour line with its two existing storage silos. The bread lines were configured so they were able to draw the flour simultaneously from the new silo as well as from the two existing silos. These plant changes resulted in the production capacity of the existing bread line being improved tremendously.

Secondly, the dosing and weighing rate of the minor ingredients had to be doubled in order to keep up with the increased transfer rate of the new flour handling system. Further, transferring the increased rate of the minor ingredients needed to be smooth. This upgrade was successfully achieved with some creative engineering. Improvements were also made to the existing water mixing unit as it was not able to attain the desired temperature. A modular water mixing unit was combined with the mixed water weighing unit for each mixer. This upgraded system was able to meter the required water at the desired temperature well before the next mixing cycle.

The plant was upgraded to being able to produce over 12,000 loaves of white sandwich bread per day. The project incurred a minimal downtime of two days for tie-in and connections to existing systems. The new flour handling system and changes to existing systems were successfully completed and delivered within budget.

The systems and components used in the material handling system for flour, minor ingredients and water in a bread line are as follows:

- Flour and water mixing system

- Flour, cracked wheat on mixers

- Inline magnetic separators

- Vacuum pumps

- Mixed water weighing tank

- Inline vacuum rotary sifter

- Wheat flour silos

- Small bag dump station for cracked wheat