A large bakery required the sequentially installation of a bread line within their existing building. Each new production line was to be added every two years. The bakery used a highly sophisticated material handling system that processed several types of flour and minor ingredients, and had many demanding technical and production requirements. Careful investigation, design and planning were required to ensure these repeated additions were feasible and sustainable.

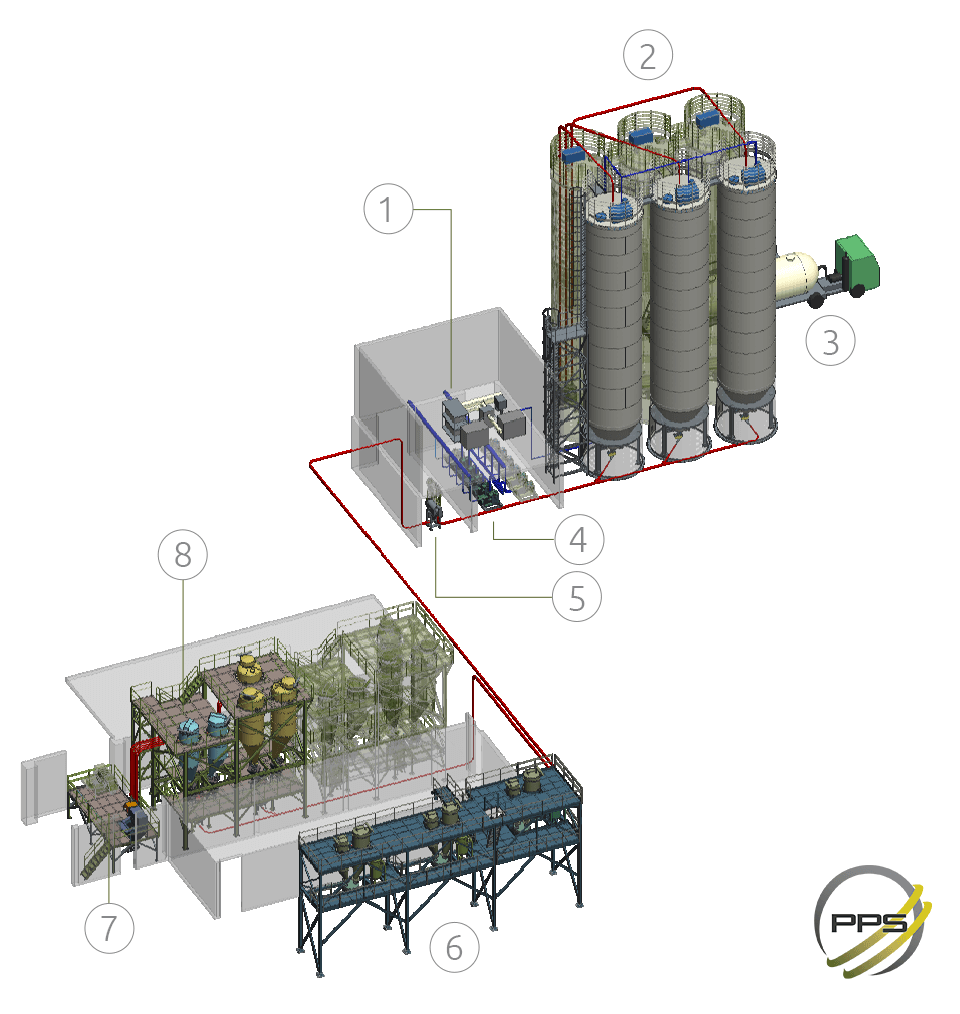

Flour, delivered by bulk trucks from nearby flour mills, is pre-sifted before transferring to specific silos. The pipes used to unload the trucks are physically labeled and equipped with pre-programmed control switches to ensure the correct flour is fed to the correct silo. Each silo is mounted on several high precision triple point weighing load cells. These enable the silo flour inventory to be physically shown at the silo base. The weight of flour in the silo is also remotely transferred to a human/machine interface (HMI) so that it can be monitored by ordering personnel.

The flour from the silos is sifted again using a heavy duty inline vacuum sifter and then passed through a magnetic separator by a negative pneumatic conveying (vacuum) conveying system. It is then weighed at the weighing hopper positioned on top of the mixer.

The raw materials for the minor ingredients come in small and bulk bags and are fed into the plant by bag tipping units. The ingredients go through an inline sifter and an inline magnetic separator before they are conveyed to indoor storage silos. Each type of minor ingredient is stored separately in an indoor storage silo. The number of silos is dependent on the number of types of ingredients.

The equipment used in the material handling system for flour and minor ingredients in a bread line includes:

- Small bag tipping system

- Dehumidification system

- Flour silos and storage system

- Flour material handling system

- Minor ingredients handling system

- Vacuum pumps

- Rotary sifters

- Flour, minor ingredients & water mixing

Some of the minor ingredients are hydroscopic in nature so a dehumidification system is used to air condition the indoor storage area. This prevents caking or agglomeration of the hydroscopic materials. The same dehumidification system is used to provide cool dry air for pneumatic conveying. The minor ingredients are pre-weighed centrally, then combined and vacuum conveyed to another weighing hopper. The batch is of pre-weighed ingredients is checked to ensure it is within tolerance.