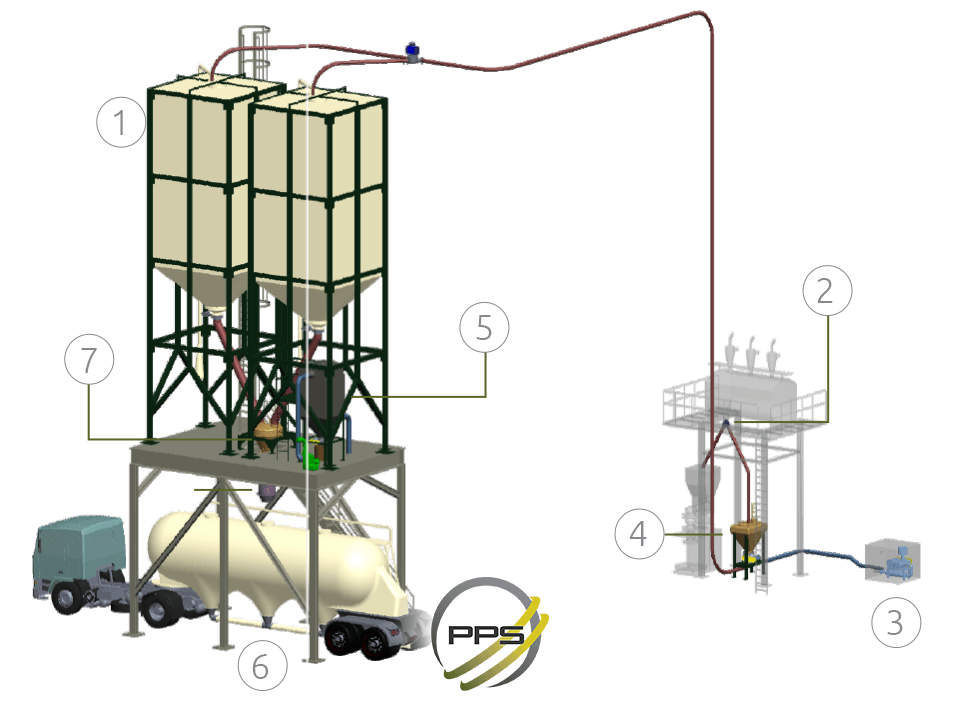

A medium-sized mill required a cost effective solution for loading bulk flour tanker from its storage silos. The best fit solution involved the installation of two flexible silos to transfer the flour from production to the tankers.

A simple gravity diverter valve was installed above the bag packing system. This allows for the transfer of flour and filling of two 30-tonne silos. A self-retracting loading spout with an integrated dust control unit is used to efficiently load the bulk tanker with no dust emission.

The flexible silos are made from high strength TREVIRA polyester, an extremely durable and tough non-toxic fabric. They are dust-proof but slightly permeable to air. This avoids condensation, which can cause product agglomeration. These silos are light and extremely resilient, made from an easily-assembled galvanized steel frame.

Flexible silos are pneumatically loaded from the top. From there, the product descends by gravity to the bottom of the silo. The vertical walls of the silo allow the product to smoothly discharge. The extraction of flour from the flexible silo is achieved through rotary airlock valves.

Project equipment

The systems and components used in the loading bulk flour tanker from storage silos are as follows:

- Dust collector

- Exhaust fan

- Flour storage silos

- Gravity diverter valve

- Loading spout

- Surge hopper

- Blower package