A food processing plant required a custom unit to cool the cocoa cakes from the cocoa press. The cocoa cakes leave the press at 90 to 100 degrees Celsius and need to be cooled to less than 40 degrees Celsius for storage. The best fit solution involved the design of a chilled water cooling unit system that used conduction, convection and heat extraction cooling methods. This system allows the cocoa cakes to be cooled in a very short time. The dust and heat extractors allow the cooling unit to be operated without any dust emission and condensation. This increased the storage and shelf-life of the cocoa cakes.

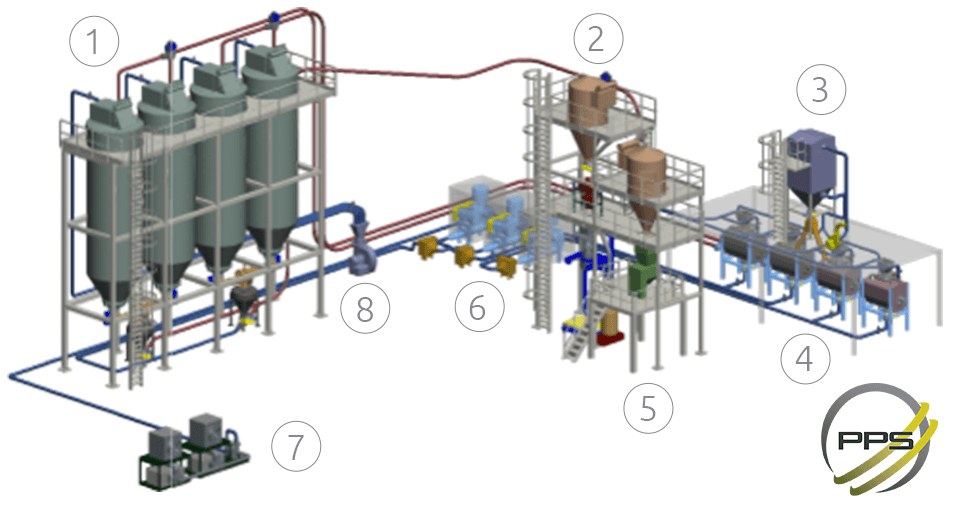

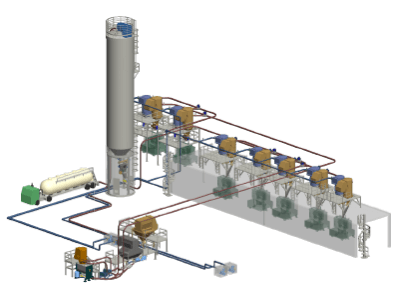

After the brief cooling, the cocoa cakes are pneumatically conveyed to silo and storage system. A secondary positive pneumatic conveying (pressure) system transfers the cocoa cakes to 25kg for packing and 1-tonne big/bulk bag for filling and packing.

In order for the cocoa cakes not to increase in temperature during conveying, an after cooler unit is required after the blower. The after cooler maintains the conveying temperature at a low level and removes the heat generated from the product impacts while being conveyed.

Custom 25kg bag packing and 1-tonne big/bulk bag filling and packing machines were used in the best-fit solution. These machines fill and pack by gross or net weight; however, specific packing machines could have been used if the food processing plant desired it. Our state-of-the art technology in weighing and loading systems enables achievement of high efficiency filling and packing with little give-away.

The systems and components used in the cocoa cake cooling process are as follows:

- After-cooler units

- Small bag filling systems

- Bulk bag filling systems

- Blowers

- Booster fan

- Cooling units

- Dust extractors

- Heat extractors

- Silos