The initial scope of the project was the installation of a simple bag tipping system; however, the recipes required small quantities of ingredients such as flour and sugar to be accurately metered to meet production requirements. This stringent requirement of metering ingredients to a high accuracy represented a major challenge.

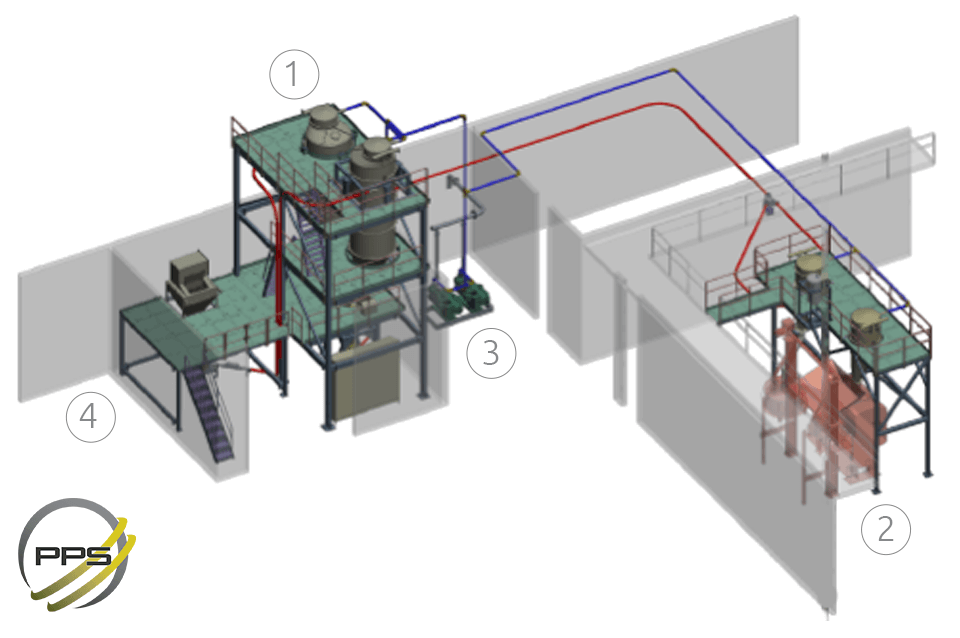

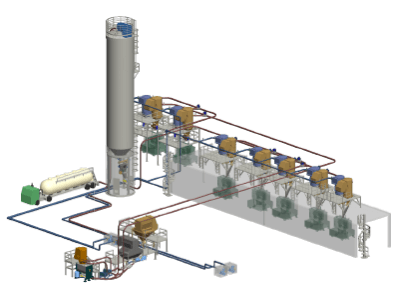

Volumetric feeders release a steady quantity of material over time, which provides an economical way to meter materials that have a consistent bulk density. In order to meet this high accuracy dosing, a system using high precision volumetric feeder meters was designed. This system allows ingredient doses, measured in grams, to be metered to a centralized weighing hopper. The pre-weighed ingredients are then transferred remotely to two weighing hoppers, using negative pneumatic conveying (vacuum).

At these hoppers the total pre-weighed ingredients are checked by the Scada recipe management system to verify the amount is within tolerance. If the pre-weighed ingredients are outside the tolerance range, the batch would be discarded and production will not be disrupted.

The high precision, high accuracy and minimum tolerance dosing process demanded a high level of expertise in precision engineering. The sophisticated project was managed in a professional manner and successfully completed.

The systems and components used in the cream roll line material handling system are as follows:

- Small bag tipping station

- Material handling for flour & sugar

- Vacuum pumps

- Vacuum weighing hoppers