After the 2021–2022 Malaysian floods, several plants were decommissioned due to the extensive damage to equipment, electrical components, and piping. Pneu Powders Systems was tasked by a client to undertake restoration and recommissioning works to get the plant running once more.

The project was challenging specifically due to the fact that the original, aged systems were not supplied or installed by Pneu Powders Systems. We were required not only to restore and reconstruct parts of the old system, but also integrate it with a new control panel and an upgraded SCADA system.

Coordination between the Original Equipment Manufacturers (OEMs), our mechanical and electrical contractors, and our design and project team were critical to the success of this project. Each piece of equipment to be restored was broken down into separate parts and the usable and non-usable pieces separated. Non-usable pieces were replaced or fabricated by our specialist fabricators. The pieces were eventually combined together once more and holistically checked before recommissioning.

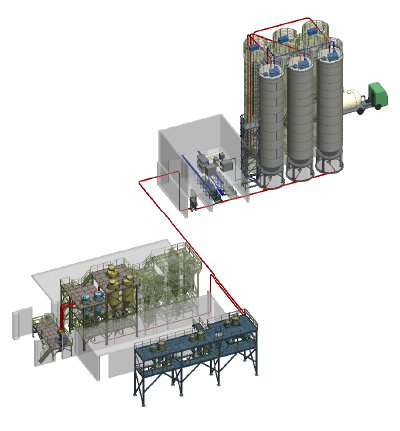

The powder handling systems and components used in the biscuit lines of this manufacturing plant example are as follows:

Whilst the original system was not supplied by Pneu Powders Systems, our expertise and knowledge of the client’s internal processes and equipment specifications allowed us to get the mixing and blending system running once more. We worked hand in hand with the client and Original Equipment Manufacturers (OEMs) to restore the system.